Automated testing through simulation

of all electrical signals

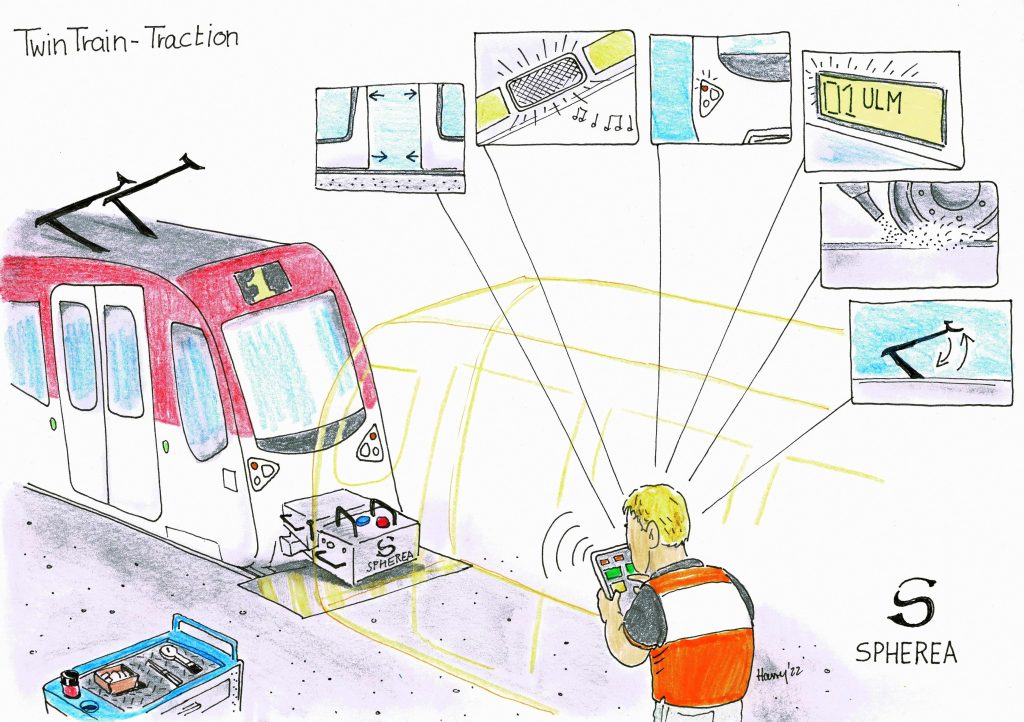

Twin Train-Traction

Product Description

A functional test of multiple traction capability can be performed without a second vehicle and by only one operator.

Modern rail vehicles offer the possibility of forming larger and smaller train units as needed. Automatic coupling mechanisms convert several individual multiple units into an entire train set. The leading vehicle controls the guided vehicle via the electric coupler. In addition to the control commands for braking and acceleration, other functions such as door control, audio announcements or passenger information are transmitted.

The reliable functioning of a train’s electric couplers ensures smooth operation in multiple traction. In conventional maintenance operations, the coupling function of a train is checked and ensured by means of another train, the so-called test vehicle.

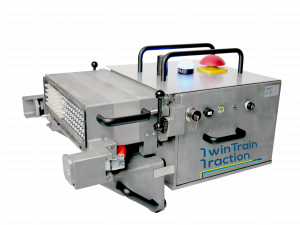

SPHEREA’s TwinTrain-Traction multiple traction testing system replaces the test vehicle. The TwinTrain-Traction simulates, tests and verifies all functions transmitted via the coupling. The test system is connected to the vehicle’s electric coupling and recognized as a coupled train. Depending on the application, the TwinTrain-Traction assumes the role of a leading or a guided vehicle. The TwinTrain-Traction ensures the safe operational readiness of all safety and information systems in the rail vehicle and offers an intuitive operating concept for performing and logging the tests.

Vorteile

Rugged design

Workshop use, indoor and outdoor use

No need for separate test vehicles

In many operations, a second vehicle is used to test a train coming out of maintenance. This fully functional part of the fleet is taken out of service for the entire testing process. Using a dedicated testing system increases the availability of the entire fleet.

Shortened maintenance times thanks to automated, uniform testing process

- To ensure that a vehicle is tested properly, the tests are automated and carried out properly according to a test specification. This is reflected at the end as a test report.

- The automated test applications enable efficient execution of all test steps. If difficulties arise, individual test steps can be repeated or a test procedure can be restarted, e.g. after repair.

One-man operation by trained personnel

- Due to a wireless operating concept it is possible to move freely around the train during the test procedure. Even the testing of all audio and display devices can thus be carried out by a single person in a short time.

- The intuitive interface shortens the training time for new personnel. Documented step-by-step instructions ensure proper testing of the vehicle.

Digital logging

- All test steps performed are properly logged. This data is available at any time for verification purposes as well as for further digital processing.

- Header data of the test protocols can be individually adapted.

Self test

Exclusion of faulty test equipment. The test system provides a neutral test environment. An important role is played by the self-test which excludes defects in the test equipment itself.

Modular

A proprietary modular system makes it possible to configure the TwinTrain-Traction for a wide variety of applications. So far, the system already supports the following protocols: IBIS carriage bus, DTMF signals, audio transmissions, Wire Train Bus (WTB), TCP/UDP via IP as well as up to any number of discrete coupling signals.

Application Area

- Maintenance and commissioning of streetcar and mainline systems

- Multiple traction tests

- Functional testing of e-couplings

- Maintenance